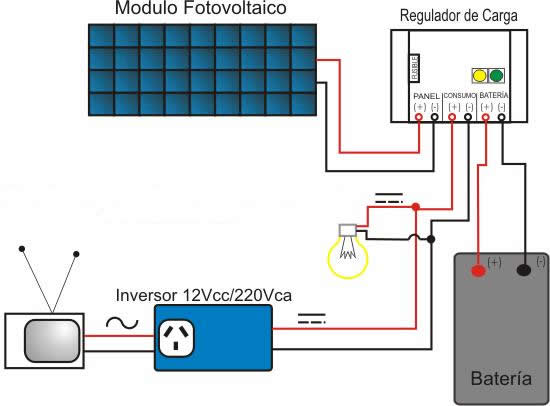

Cables, both direct current (DC) and alternating current (AC), if correctly sized, will minimize energy losses and protect the installation.

For a photovoltaic system, DC cables must meet some requirements:

* Have grounding line and protection against short circuit.

* Be resistant to UV rays and adverse weather conditions with a wide range of temperatures (approximately between -40ºC and 110ºC).

* Possess a wide voltage range (more than 2000 V).

* Be simple and easy to manipulate.

* Be non-flammable, of low toxic level in case of fire and without halogens.

* Have a very low conduction loss (up to 1%).

Photovoltaic installation cables must have certain characteristics that differentiate them from conventional cables, although many argue that differences are not very large.

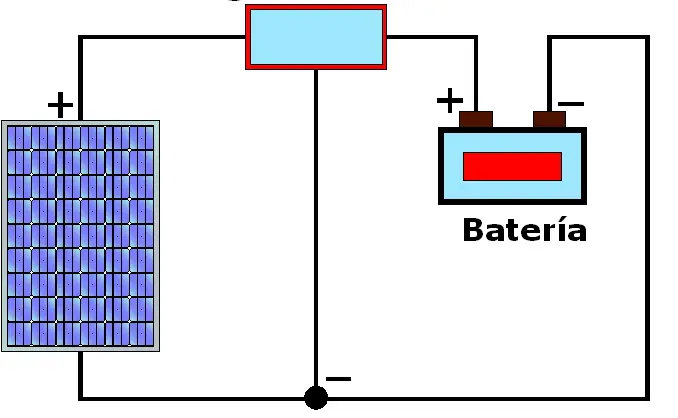

Since voltage in a photovoltaic system is low DC voltage, 12 or 24 V, currents that will flow through the cables are much higher than those in systems with 110 or 220 V AC voltage.

Power amount in Watts produced by the battery or photovoltaic panel is given by the following formula: P = V. I

V = voltage in Volts

I = current in Amperes

This means that to supply a power at 12 V current will be almost 20 times higher than in a 220 V system. It implies that much thicker cables must be attached to prevent overheating or even a fire.

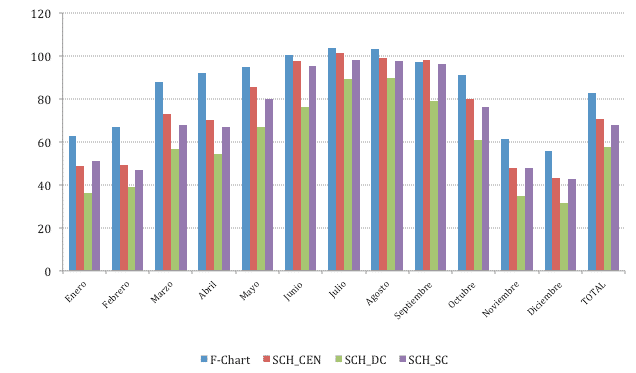

Following table indicates recommended cable section according to power and for different voltage levels.

For very low voltages and low power demands, very thick cables must be used. For example, to reach a power of approximately 1 Kw at 12 V we would need a 25 mm2 section cable. The same as to supply 20 Kw at 220 V.

This increases system price drastically because thicker cables are more expensive.

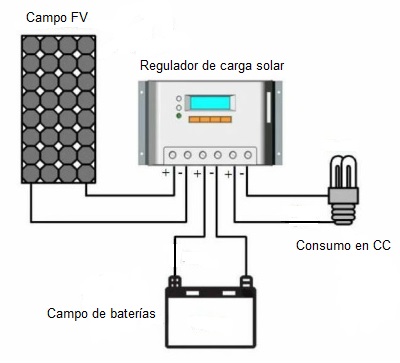

That is why it is very important that the lengths of DC wiring are as short as possible.

When designing large systems, a cost / performance analysis must be performed to choose most suitable operating voltage. It would be advisable to gather small groups of modules and if possible to make operating voltage higher than 12 or 24 V.

To verify cable section values recommended in tables, maximum voltage drops compared to voltage at which you are working should be below the 3% / 5% limit.

To calculate the relationship between conductor section and its length we can apply following formula:

S = 2 r. l. i / ΔV

Being:

r Conductive material resistivity (0.018 in case of copper conductors)

l Cable section length

i Current intensity

ΔV Voltmeter reading difference

Let’s see an example:

Battery terminals output voltage is 13.1 V. The main line between it and a device, which consumes 60 W, measures 12 m of 6 mm2 cable.

We must find the voltage value at device input to verify that we are within maximum recommended values of voltage drop.

The intensity i = P / V = 60 / 13.1 = 4.6 A

S = 6 = 2. 0.018. 12 4.6 / ΔV

ΔV = 0.33 V

Therefore, voltage at device input will be: 13.1 – 0.33 = 12.8 V

Voltage drop is 2.34% (maximum recommended value: 3%).

It is normal to use tables to select recommended section and use the formula to calculate the voltage drop and perform the verification.

In case that voltage recommended maximum values drop are exceeded, we will select section immediately above and we will carry out verification again.

Cables for photovoltaic applications have a designation, according to regulations, which is composed of a set of letters and numbers, each with a meaning.

Cables designation refers to a series of characteristics (construction materials, nominal voltages, etc.) that facilitate the selection of the most suitable to the need or application.

This is an extract of contents included in Technical-Commercial Photovoltaic Solar Energy Manual and Sopelia e-learning training.

All you need is Sun. All you need is Sopelia.