Previous clarification: we are in favor of renewable energy in general and solar energy in particular. We dedicate ourselves to that.

This does not prevent us from taking a critical look at how the sector is developing.

Making the parallel with a famous rear, on the one hand we have “the resistance” (individuals and companies) and on the other, “the dark side” (public administrations and energy trading companies).

The discourse is that renewable energies, in addition to helping us combat climate change, will provide us with energy independence.

Our territory is full of solar and wind farms and more and more photovoltaic systems are being observed on the roofs.

But the reality is that energy price in some countries has increased almost fivefold in the last 2 years and that solar self-consumption benefits, in most countries and mainly in residential sector, vanish in tolls and unclear compensation systems.

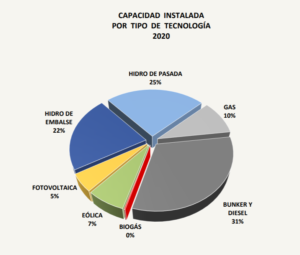

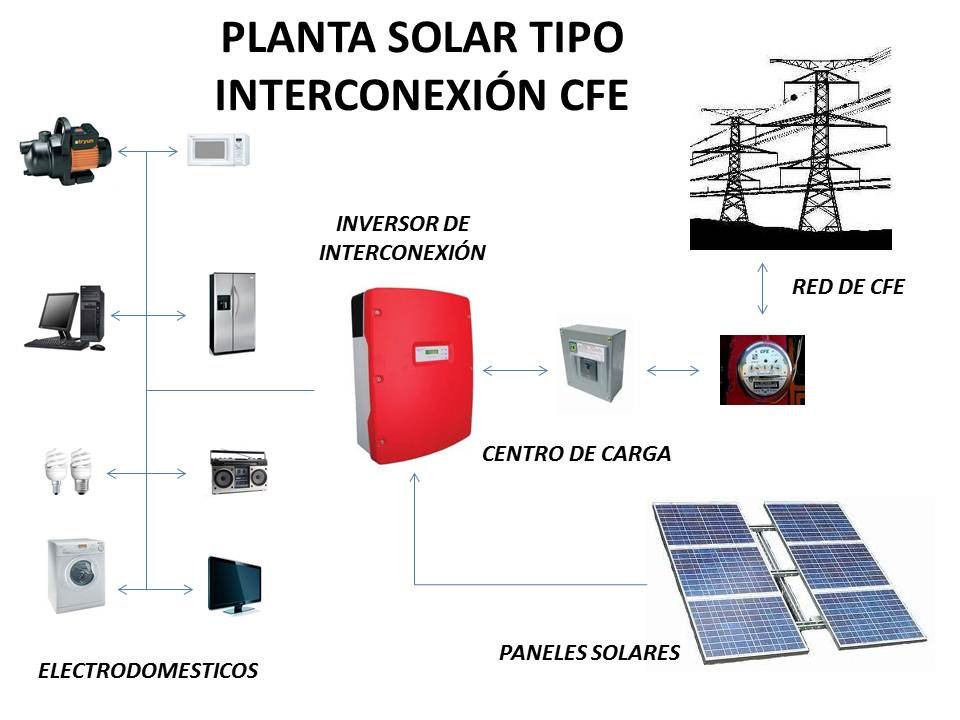

In case of large-scale renewable systems, coupling energy generated with distribution network is still inefficient. To assess its location, in most cases scientific, technical, ecological, economic and social criteria have not been used to minimize its impact on the landscape, biodiversity and the way of life of the inhabitants of the affected territories.

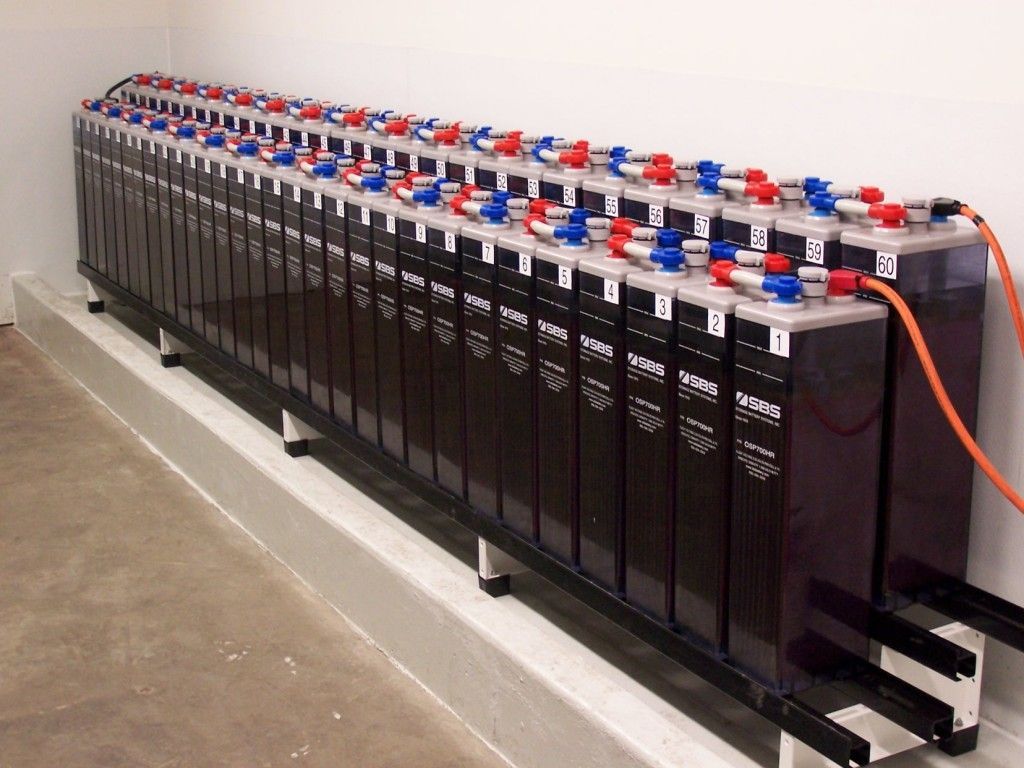

As for solar self-consumption systems, currently they are only interesting in those activities in which solar radiation hours coincide with energy consumption hours.

Making the parallel with another well-known rear, to overcome these obstacles we must find the holy grail as soon as possible: an efficient and cheap energy storage system.

Meanwhile “the dark side” continues to beat “the resistance” by a landslide. One of its members regulates the sector with regulations and procedures for setting rates tailored to the interests of the other, and the other member is a voracious tax collection agent for the former.

We have other bad news … doing things right way is against the interests of “the dark side.”

How should things be done? Relying on 3 basic pillars:

1) Energy efficiency

Making more efficient use of available resources runs counter to the established idea that increasing GDP is synonymous with progress. It would involve manufacturing more energy efficient devices and reducing their planned obsolescence. In short, use fewer resources and generate less waste. Or what is the same, give priority to the environmental quality over the economic quantity.

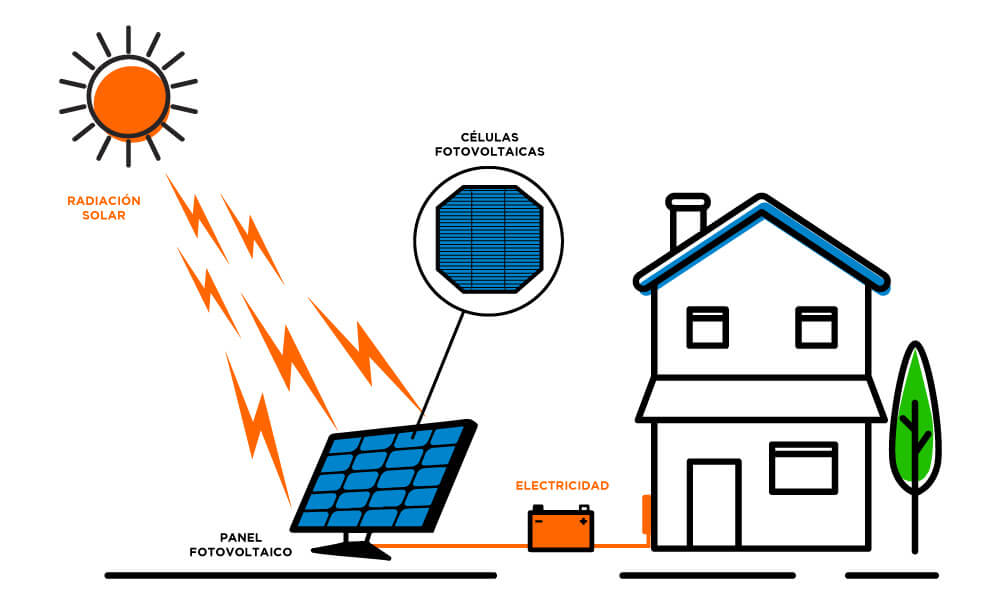

2) Renewable energies

Of the 3 pillars, it is the only one in which there is consensus and in which the most progress has been made. The replacement of fossil resources that produce the greenhouse effect with renewable resources for power generation is practically out of question.

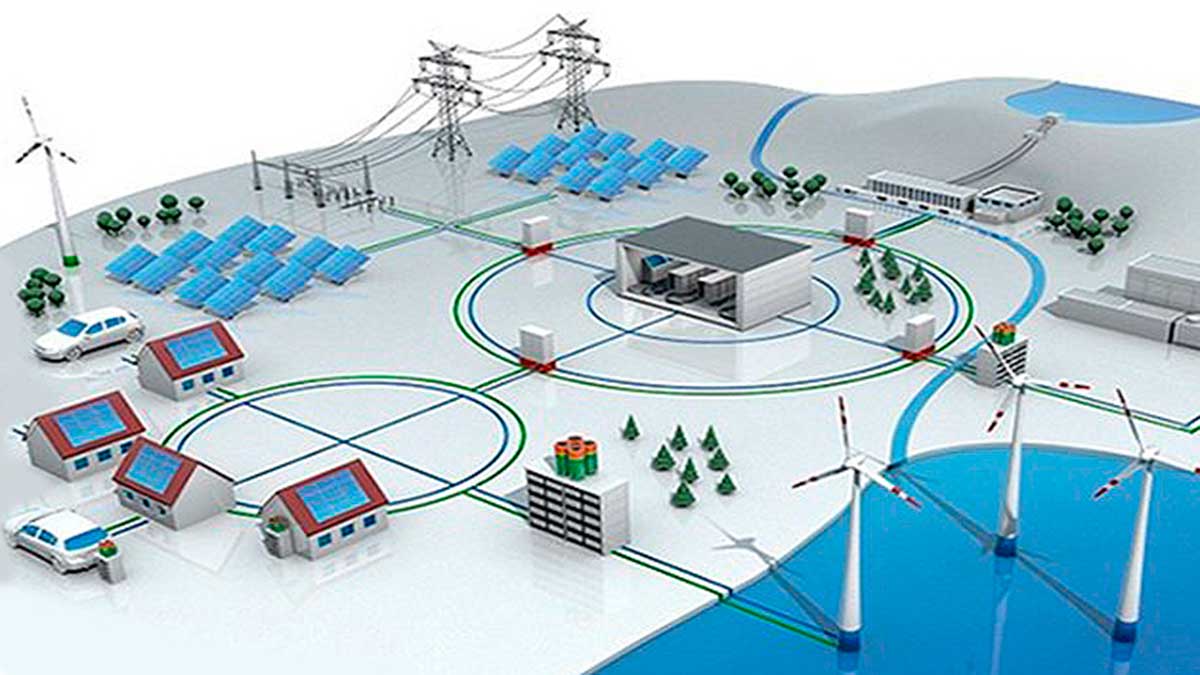

3) Distributed generation

Here, too, the clash of interests occurs. Distributed generation is synonymous with energy independence and this does not interest the “dark side”. It would imply less control, fewer tolls, transparent or zero compensation systems, and less tax collection.

Distributed generation entails decentralization in interconnected generation cells and consequently the minimization of losses caused by energy transport. Power generation is close to consumption points, favoring self-consumption. This translates into energy savings, cost reduction and energy system transparency.

Using sites in urban and industrial areas (roofs) close to consumption points would have a lower impact on biodiversity.

The opposite of centralization and control. With a centralized energy network like the current one, energy is generated in plants located at great distances from consumption places. This requires a complex transportation and distribution infrastructure. From an economic point of view it represents a high profitability for its operators, but it entails a high environmental impact and a high performance loss (close to 20%); motivated by the transformation processes necessary to transport electricity.

Is important the contribution of small-scale solar thermal energy with a performance twice that of photovoltaic solar energy.

Many countries, such as Spain, have incorporated it as an essential requirement for obtaining a building license for any new building.

This is very positive, but unfortunately we can affirm that approximately 4 out of 10 of these facilities do not work properly because the inspection is limited to obtaining the building license and not to its operation and subsequent maintenance; as in the case for example of a gas boiler.

Both “the resistance” and “the dark side” know that this is the way.

But the first is scattered and only has the strength to rise from time to time a few ephemeral media characters and the second continues to pull the strings in the shadows with the sole objective of maximizing its benefits.

From time to time they meet to take a photo and issue empty statements of intention of concrete objectives and plans and assign million-dollar budget items that one knows where they will go. The last one was in Rome last October.

From Sopelia we encourage you to join “the resistance” and to continue fighting against climate change, each one in his field and in his day to day because as a friend of ours says: there is no planet B.

All you need is Sun. All you need is Sopelia.