In solar thermal energy systems, heat exchanger is in charge of transmitting the heat energy collected by solar collectors to medium that needs to be heated.

Depending on type of heat transfer system used, they can be classified into:

• Direct: Domestic hot water for consumption circulates through primary circuit and, therefore, will circulate through collectors. This system is suitable for small systems located in areas where there is no freezing danger. The trend is towards the restriction of its use, not being admitted in several countries.

• Indirect: Domestic hot water for final consumption circulates only through secondary circuit, which means that heat transfer liquid only flows through the primary circuit and is never in contact with domestic hot water. In this case, an exchanger is needed to pass the heat collected in first to second circuit.

The selected exchanger will withstand the maximum working pressure of the system.

According to section HE-4 of Spanish CTE:

– In case of an independent heat exchanger, the minimum power of heat exchanger P will be determined for working conditions in day central hours, assuming a solar radiation of 1,000 W / m2 and a performance of solar energy conversion to heat of 50 %, fulfilling the condition:

P = 500. A

Being:

P = minimum power of the exchanger [W]

A = the collector area [m2].

– In case of an exchanger incorporated into the accumulator, the ratio between useful exchange surface and total collection surface shall not be less than 0.15.

In each of water inlet and outlet pipes of the heat exchanger, a shut-off valve will be installed next to the corresponding sleeve.

The heat exchangers used in sanitary water circuits will be made of stainless steel or copper.

The design head loss in the heat exchanger shall not exceed 3 m / ac, both in primary and in secondary circuit.

Solar exchangers type:

Plate heat exchanger: This type of heat exchanger is made up of a series of corrugated metal plates, joined together in a frame by pressure and sealed by a gasket. Plates form a series of interconnected corridors through which working fluids circulate. These fluids are powered by pumps.

In order to choose correct plate heat exchanger for the system, it is necessary to consult the manufacturer’s guidelines. However, it is recommended that the thermal power to be transferred (in Kw) is equal to 2/3 of the collecting surface (in m2).

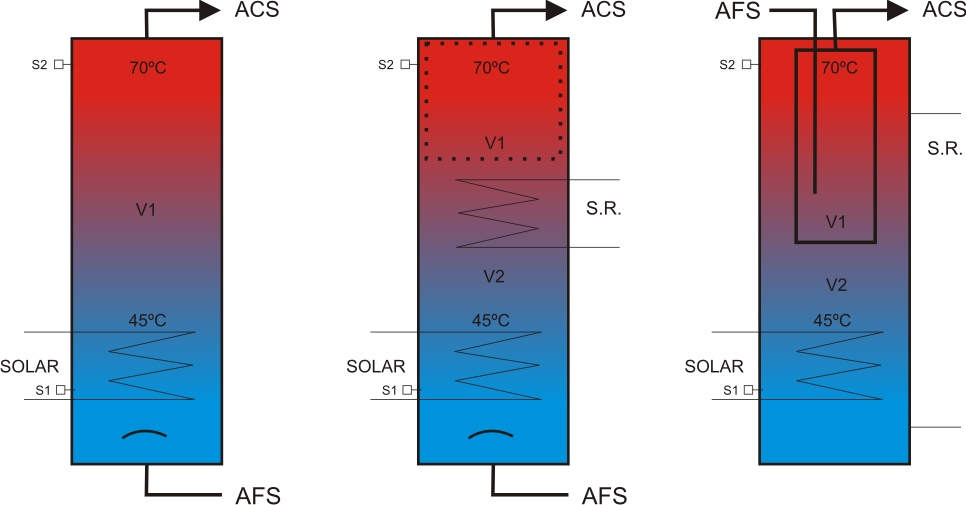

Double wrap exchanger: this system consists of a tank in which the secondary fluid (hot water) is accumulated and which has a double wall through which heat transfer fluid circulates, giving heat to domestic hot water.

Exchanger’s operating conditions dictate the choice of its material, which is usually carbon steel or alloy steels. Minimum exchange surface must be between 1/4 and 1/3 of useful collectors surface. However, there is a geometric limit to its use, which is given by housing dimensions. For a certain range of measurements, exchange surface can become less than a quarter collector surface. For volumes greater than 750 liters, the necessary exchange surface (which is the accumulator wall) is increasing and could result in very high accumulators for which it would be necessary to have a suitable machine room.

Coil exchanger: is made up of a tube that is submerged in a tank where the secondary fluid accumulates. The primary or heat transfer fluid circulates inside the tube, giving heat to the secondary fluid.

According tube shape they are distinguished:

• Helical coil exchanger. The spiral wound tube that carries heat transfer fluid is submerged inside accumulator at the bottom.

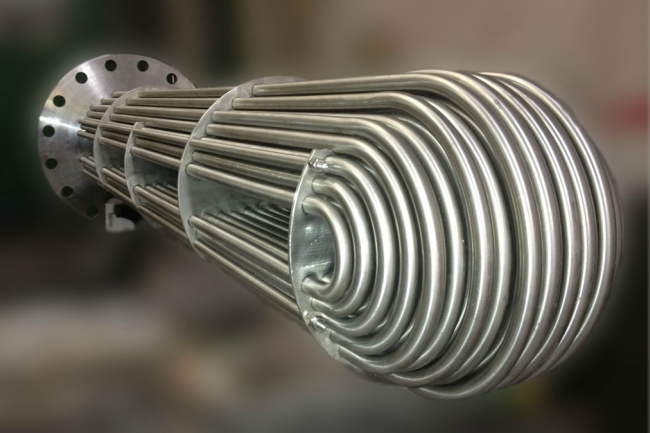

• Tube bundle coil exchanger. They are commonly used to obtain ACS. Primary fluid circulates through several tubes, not one as in the helical. Liquid flows inside coil by forced circulation, while outside the fluid in contact with coil is renewed by natural circulation.

To know if a coil heat exchanger is suitable for use in solar applications, its minimum exchange surface must be between 1/4 and 1/3 of collectors useful surface.

The exchange surface of a helical coil or tube bundle will be the lateral surface of a cylinder based on outer section of the tube used and by height total length of the same. With this criterion it will be easy to size a tubular exchanger.

Some recommendations:

– The coil must be placed in the lowest part of accumulator.

– If it is helical, distance between turns should be equal to 2 times outer diameter of the tube.

– If we use antifreeze in a proportion of up to 30%, exchange surface must be increased by 10%.

This content was extracted from the Solar Thermal Energy Technical-Commercial Manual and is part of Solar e-learning.

All you need is Sun. All you need is Sopelia.