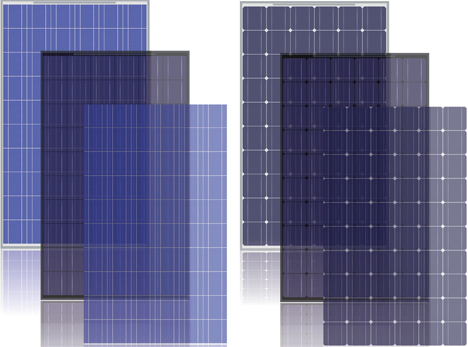

Coupling of two or more modules in series produces a voltage equal to the sum of individual voltages of each module, keeping the intensity unchanged.

In parallel connection, it is the current that increases while voltage remains the same.

The most common is to select modules of desired voltage (those of 12 V are the most used) and combine them in parallel so that the total intensity (and therefore resulting power) is necessary to satisfy the electrical demand.

Interconnecting modules must have the same i-V curve to avoid decompensation.

If in a group of modules connected in series one of them fails (due to failure or shade), this module becomes a resistive load that will hinder or prevent the passage of the current generated by the other modules in the series. The module in question could be totally damaged.

To prevent this situation, modules connected in series are equipped with a by-pass or bypass diode, connected in parallel between their terminals. This element provides an alternative path to current generated by the other modules in the series.

There are different types of configurations that respond to systems characteristics and especially to load type. Most common ones are detailed below:

• Modules directly connected to a load

It is the simplest system. Photovoltaic generator connects directly to the load, normally a direct current motor. It is used for example in pumping water. In absence of batteries or electronic components, reliability increases but it is difficult to maintain efficient performance throughout the day.

• Modules and battery

This setting can be used to replenish self-discharge of a battery or in small power rural electrification systems. One or two modules connected in parallel are usually used to achieve the desired power.

• Modules, battery and regulator

In this configuration, photovoltaic generator is connected to a battery through a regulator so that it is not overcharged or reaches an undesired depth of discharge. Batteries supply loads in direct current.

• Modules, battery, regulator and inverter

When AC power is required, an inverter will be incorporated into the scheme of previous configuration. Power generated in the photovoltaic system can be completely transformed into AC or DC and AC loads can be simultaneously supplied.

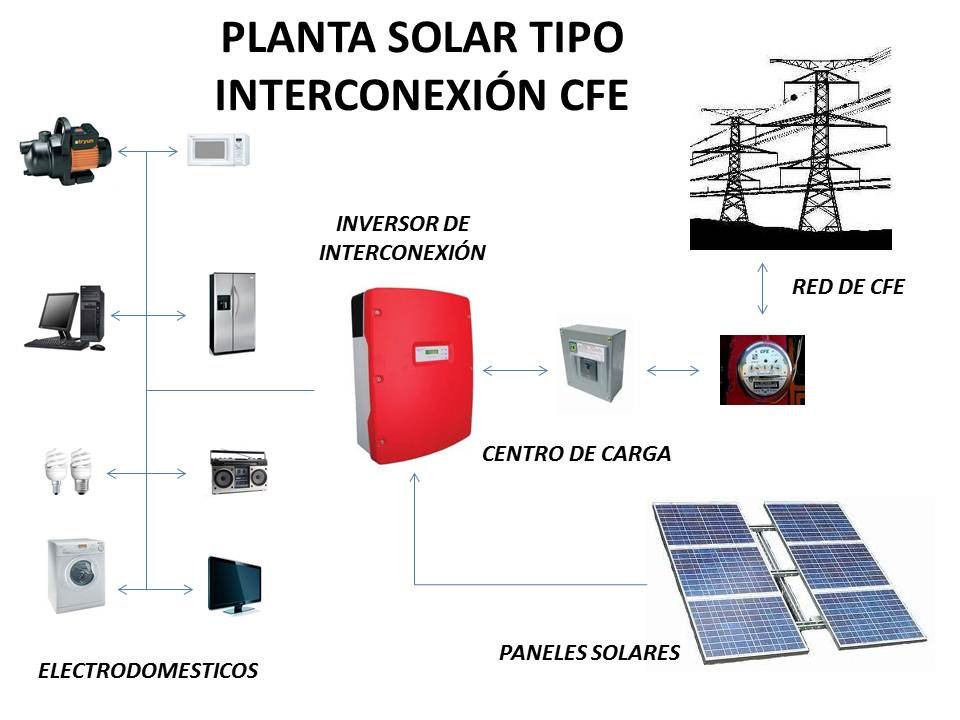

• Network connected systems

Grid-connected photovoltaic systems are made up of a photovoltaic generator that is connected to the conventional electrical grid through an inverter.

There may be two cases:

– The system injects energy into the network when its production exceeds self-consumption, and extracts energy from it otherwise.

– The system only injects energy into the network.

Fundamental difference between an isolated photovoltaic system and those connected to the grid consists in the absence, in the latter, of the battery and charge regulation.

The inverter, in grid-connected systems, must be in phase with the grid voltage.

Here are some examples of photovoltaic systems:

– Centrals connected to network with subsidy production.

– Microwave and radio repeater stations.

– Villages electrification in remote areas (rural electrification).

– Medical facilities in rural areas.

– Electric current for country houses.

– Emergency communication systems.

– Environmental data and water quality surveillance systems.

– Lighthouses, buoys and maritime navigation beacons.

– Pumping for irrigation systems, drinking water in rural areas and watering holes for livestock.

– Beaconing for aeronautical protection.

– Cathodic protection systems.

– Desalination systems.

– Recreational vehicles.

– Railway signaling.

– Systems for charging ship accumulators.

– Power for spaceships.

– SOS posts (road emergency telephones).

– Parking meters.

– Recharge of scooters and electric vehicles.

This content was extracted from the Commercial Technical Manual of Photovoltaic Solar Energy and is part of Sopelia Solar e-learning.

All you need is Sun. All you need is Sopelia.