Haiti is one of the poorest countries in the world, where electricity is only available for very few people, while the vast population majority can only rely on kerosene lamps for lighting and on wood from the forests for other uses.

For a long time, Haiti has suffered problems in its energy supply, so much so that more than 70% of its population does not have daily access to a reliable electricity source.

The country covers all of its energy demand with supplies from Petrocaribe, a regional project that benefits 18 Caribbean region countries to which Venezuela supplies oil and oil products under favorable payment conditions.

It is also part of Petrocaribe Energy Security Treaty (TSE), signed in 2007, by which signatory nations made a commitment to develop, as far as possible, projects for renewable energies promotion.

Since 2010, the Inter-American Development Bank (IDB) has provided funds to Haitian government to develop a new energy infrastructure that takes advantage of country’s wind, solar and hydroelectric potential.

Among the projects financed are Peligre hydroelectric plant rehabilitation, country’s largest renewable energy source.

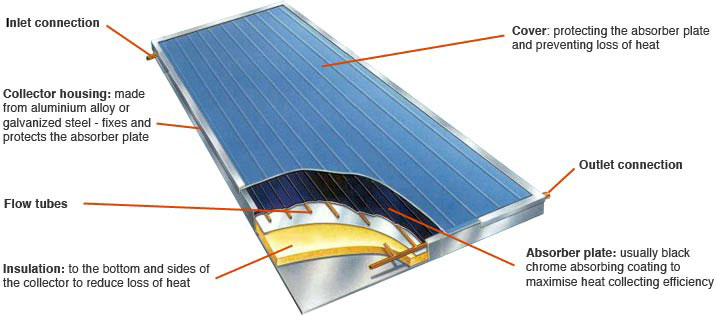

The institution also funds projects to develop solar energy use as energy source in health and education sectors.

Devastating consequences caused by frequent earthquakes in much of the Caribbean country leave population exposed to social instability dangers still present.

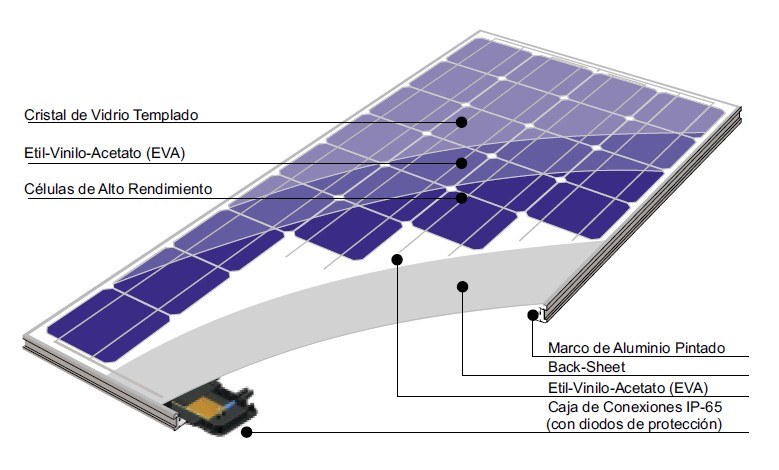

One specific action is mobile water treatment plants use, which allow different types of water purification and obtain productions from 500 to 7,500 liters / day, according to the water source; only with the energy of its 3 photovoltaic panels.

Charcoal (70% of national energy consumption) is the main energy source in kitchens of majority Haiti inhabitants, lacking in electrical energy. The result is that today forest area only covers 2% of territory.

Deforestation is a direct cause of soil erosion, which increases Haiti’s vulnerability to extreme weather events such as hurricanes, droughts and floods that may be more intense each year as a climate change result.

But little by little, renewable energy makes its way.

Toussaint Louverture Avenue, one of main arteries of Port-au-Prince, lights up every night with its solar lamps; as well as other public spaces of this capital and some municipalities of the country.

The Nouvelle Grand Anse Fundation has signed an agreement with the NGO Cubasolar to create in Dekade town a renewable energy reference center for surrounding region and the whole country.

Haiti president-elect made a tour of energy plants in Dominican Republic in early 2017.

He visited plants of Punta Catalina project (2 coal plants), Monte Plata Solar project and AES Dominicana consortium’s electricity generation plant; which supplies 40% of the energy consumed by the country.

It’s a good gesture.

Dominican Republic and Haiti must normalize their relations, as Dominicans and Haitians must work together and collaborate to improve their energy generation matrix.

All you need is Sun. All you need is Sopelia.